I can hardly believe that this blog entry only covers a 4 week period… it was difficult, stressful, chaotic, exciting and most of all productive and rewarding! Many years ago I agreed to do a Sydney to Hobart Race as a bowman on a leaky 40 footer… I will never forget the thought that crossed my mind about 30 hours into the 5 day race as I was holding on for dear life.

Alone on the bow of a boat that was spending 50% of time scuba diving under monstrous waves and the rest climbing grey cold mountains of water of a height I had never seen before – I was hand tying a tiny storm jib onto the forestay, no one onboard had had any sleep since the start of the race, one guy was unconscious down below and another had just vomited into our kettle – we were getting smashed and there was a lot more to come – I really felt I had reached my limit already and wondered out loud "How the F%#k am I going to survive this??!"

Mile by mile we inched towards Hobart, and dealt with 3 separate storms, we laid the boat over on its side in the middle of bass strait, patched up the owner who had split his head open, and nursed the crew and the boat alike – but we held on and managed a podium finish with a respectable third in our division….

For some reason, for the first time since that race, that same thought kept on crossing my mind time and time again last month… "how am I going to survive this??!" I was working 15 hr days, on site from 7:00 am till 5pm, 6 days per week and then going home and adjusting 3D and CAD drawings to reflect the day’s changes, chasing materials, engineers, certificates and more, often going to bed well after midnight… most nights I was lucky to manage 5-6 hrs sleep, but the excitement meant i was often waking up at 5:00 am finishing off drawings and couldn’t wait to get back on site – we got there in the end and the ground floor is done!

The chaos started when I took a trip to Windsor on a Sunny Saturday to pick up some materials…

2 hrs later, I was stuck in a crazy hail storm….

Trying to work out if this was some sort of sign to give up now!

I didn’t give up and pressed ahead to try and get Matt and the guys from KVA to commit to start on my slab the following week – it wasn’t looking good…

As it turned out, that storm meant that a number of other jobs were put on hold as the sites were all flooded – I got a phone call from Matt late on a Friday – all the steel and materials would arrive on Monday for a Tuesday or Wednesday start…

The waffle pods were delivered without incident… however I hadn’t allowed for the big crane truck to deliver the steel….

Someone had parked their car in front of the site and I had to make a decision to either send the steel truck away or to dump the 100’s of KGs of steel on the footpath and hand carry it in… a quick call to the ranger and I got a verbal OK to temporarily put the steel on the road.

Captain Ash and Pappa G (my dad) got a call up to come and help me carry the steel on site.

Before long the steel was on site and we closed up shop for the day.

The next day Matt and the boys were on site at 6:30 and got straight into setting up the slab formwork.

The next day Matt and the boys were on site at 6:30 and got straight into setting up the slab formwork.

… by 10 am however they had walked off the site as it turned out that i hadn’t excavated the site enough…. Rookie error by the Rookie of the year…

The entire site was about 3-5cms too high – might seem trivial, but by the time you add it all up it was close to 8 tonnes of dirt!!

I called my old mate Mick, and miraculously he had just finished a job faster than expected and had the afternoon free – he could be there by 1pm… this was the biggest lucky break I could have hoped for!

Mick and I worked tirelessly and by 5pm he had excavated the bulk of it and had taken one load to the tip and promised to be back at first light to finish off the remaining 3-4 tonnes!

I checked and triple checked the site with levels, a laser and cross checked RL measurements – the site was once again ready… I called Matt to let him know and he said he would ask his guys if they were interested in knocking it over on a Saturday so that we could stick to the schedule of pouring concrete the following week… two guys agreed and I offered to be a first year apprentice and help out – we were back once again.

7:00 am Saturday, one guy turned up with no tools and no truck – Smithy, the no-show young gun, was meant to pick up the truck and a labourer at 4:30 am in Penrith – he had slept in and no one could get in touch with him…. so down to 1 man and me, we decided to press on – I raced to bunnings and bought the necessary tools – borrowed a laser level and we were underway.

At 9:30 am we were surprised when a sheepish and hung over looking smithy pulled up in the truck – you beauty… this was again starting to go well..

With 2 guys that know what they’re doing and me trying to keep up, the pace increased and we were starting to get somewhere.

Mum dropped by for a quick inspection.

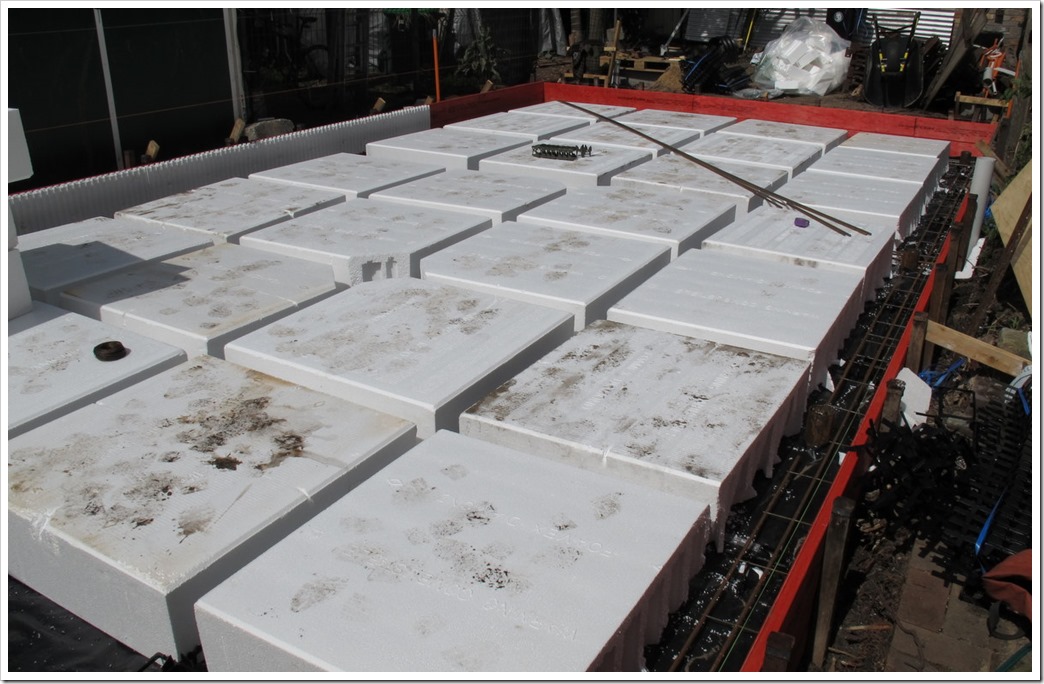

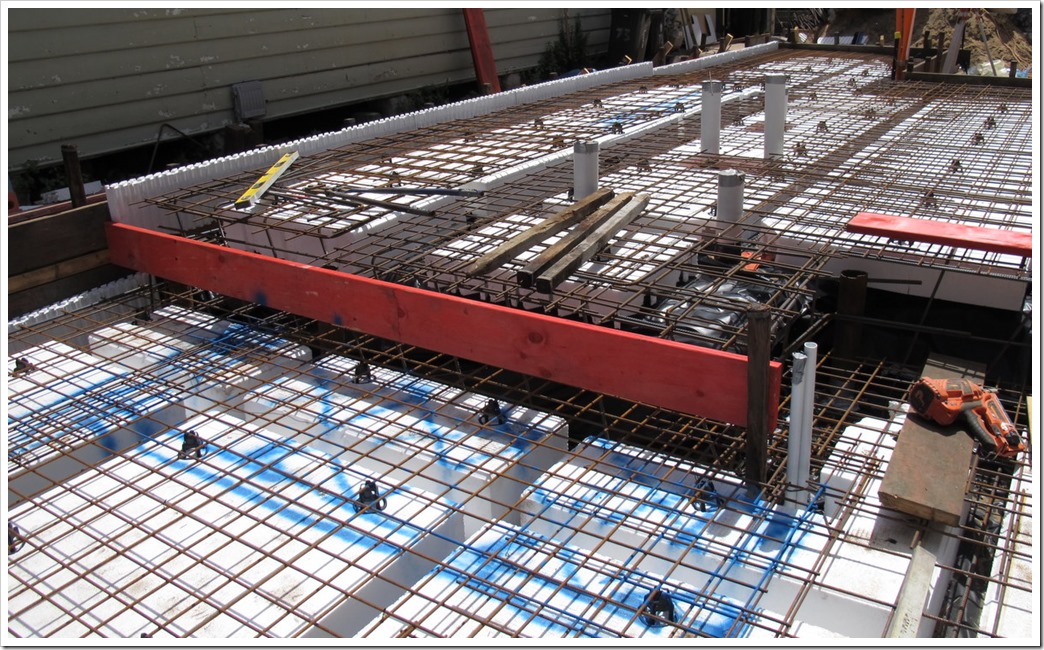

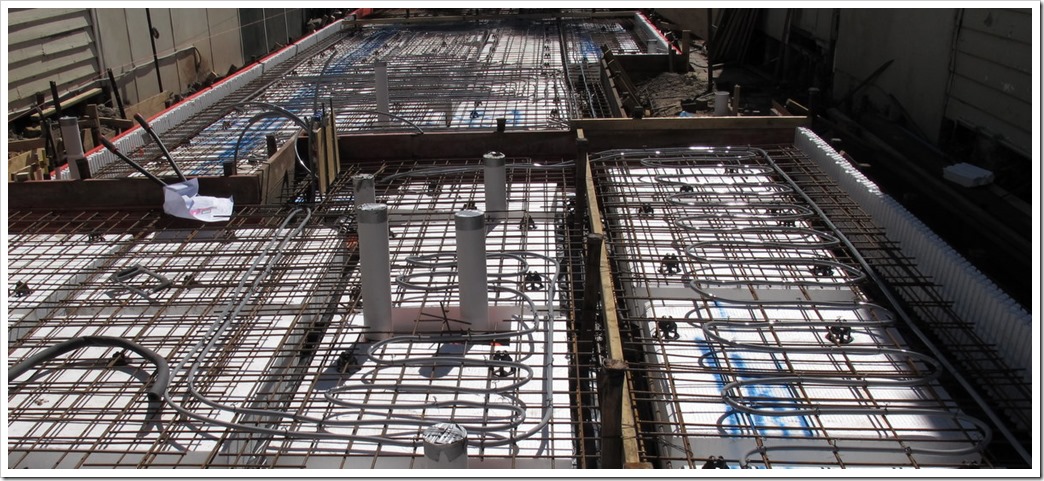

All in a days work – Plastic, waffle pods, reinforcing steel – working well into the afternoon.

at 5:30pm the boys called it quits, not before we shared a couple of well deserved cold beers!

Matt being the legend that he is, cut short his long weekend away and came back on Sunday night in order to come and finish off a few bits and pieces on Monday morning before the Wednesday pour!!

As it turned out there was still quite a lot to do and the day was saved once again….

Still a few edge boards to go in for the step downs… pushing the clock to the last minute.

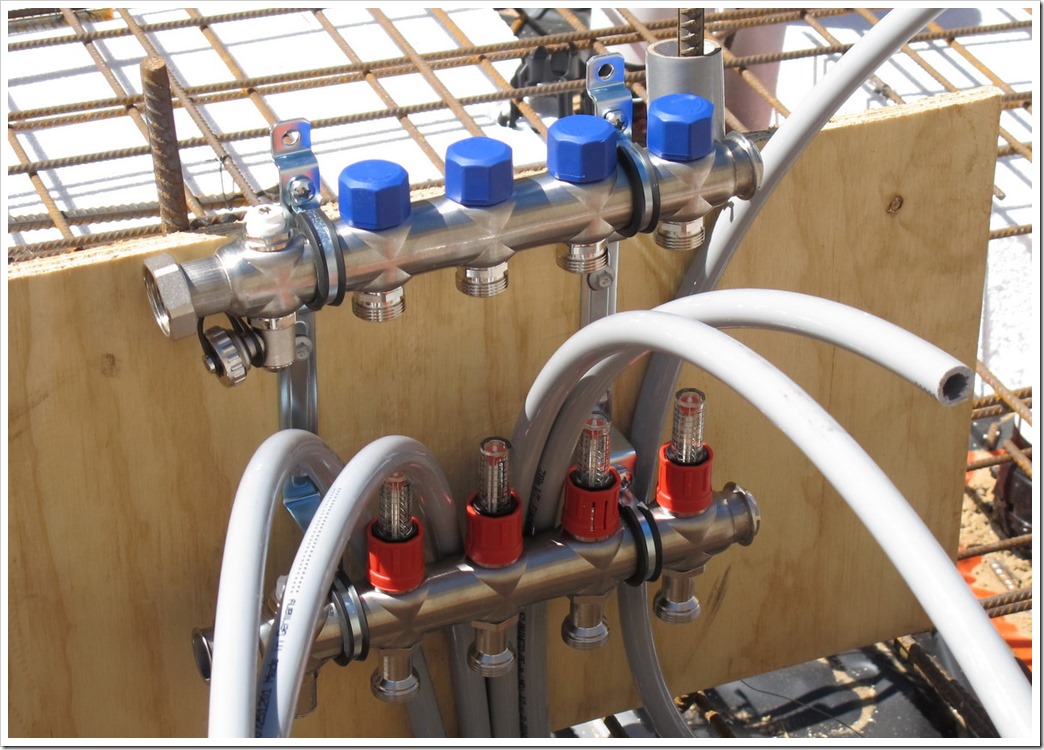

As soon as Matt’s crew left, the Hydronic heating guy turned up – again without a sidekick due to unforseen circumstances… So I was back on the tools again, this time helping install hydronic heating

I was another late finish, working till 6pm or so….

The manifold connections almost ready for the final test

These gray pipes will be filled with hot water in winter thus heating up the slab and keeping the house warm.

The pressure gauge doesn’t lie – the system is charged and looks to be leak free.

Sun getting ready to set as we finish up with only 12 hrs left before the concrete trucks arrive….

The pump truck is in place early… a good day for a concrete pour!

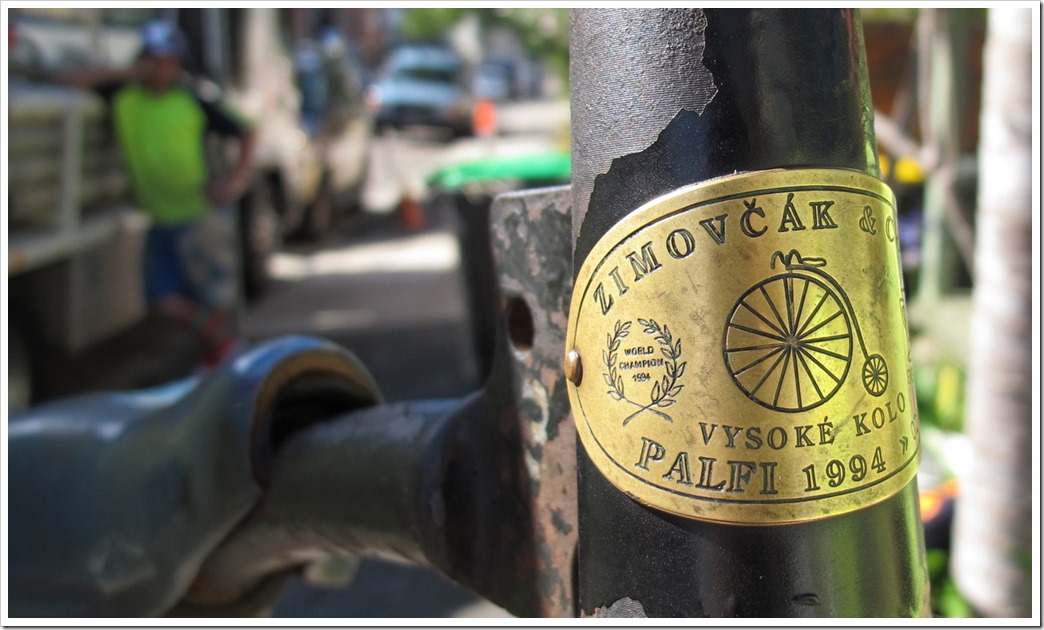

Hugh, my next door neighbour, entertaining the boys with his penny farthing skills.

As soon as the first concrete truck arrived, it was down to business.

Matt ran a very tight operation and the day ran like clockwork.

The first bit of concrete….

… and it was all hands on deck!

A quick break in between concrete deliveries.

And Hugh is at it again…

The "penny" is not as old as it seems.

… and back to work!

Messy work!

Showing off some tricks of the trade!

By early afternoon, the slab was poured.

Matt finishing off with the helicopter!

Final touches!

and presto – 1 finished slab!

The following day we waterproofed the edges (white paint) and drilled & epoxied in the starter bars for the walls – the guys from KVA also came back and stripped the formwork – amazing how fast it all happens when you get on a roll.

It felt good to be "out of the ground"!

Next morning the Wall Braces arrived…

Followed by the Zego Insulated Concrete form (ICF) building blocks….

… and 2 tonnes of reinforcing steel for the walls.

The southern wall starting to take shape…

The maze begins to take shape

Simon’s trusty Holden Rodeo has been a godsend for picking up materials.

Organising material storage on a 190m2 site is not easy

Peter setting up the scaffolding planks, with Trevor in his usual ‘supervisory’ role.

It Will be an interesting challenge rendering between buildings!

We’ve been lucky with the weather so far…

With a week to go before the concrete pour, things were looking ok – however the supporting beams that needed to be formed up hadn’t yet been started – the only thing to do was to outsource to some specialists. 14 days before Christmas was not a good time to ring around looking for people to start the next day. I managed to get one guy to come onsite and quote it, but he called me the next day to let me know he couldn’t do the job, but he knew someone who could and who would honour the quote… you beauty!!

A day later the job was underway…

And the maze got more complicated yet again!!

The soffit going in for the beam formwork.

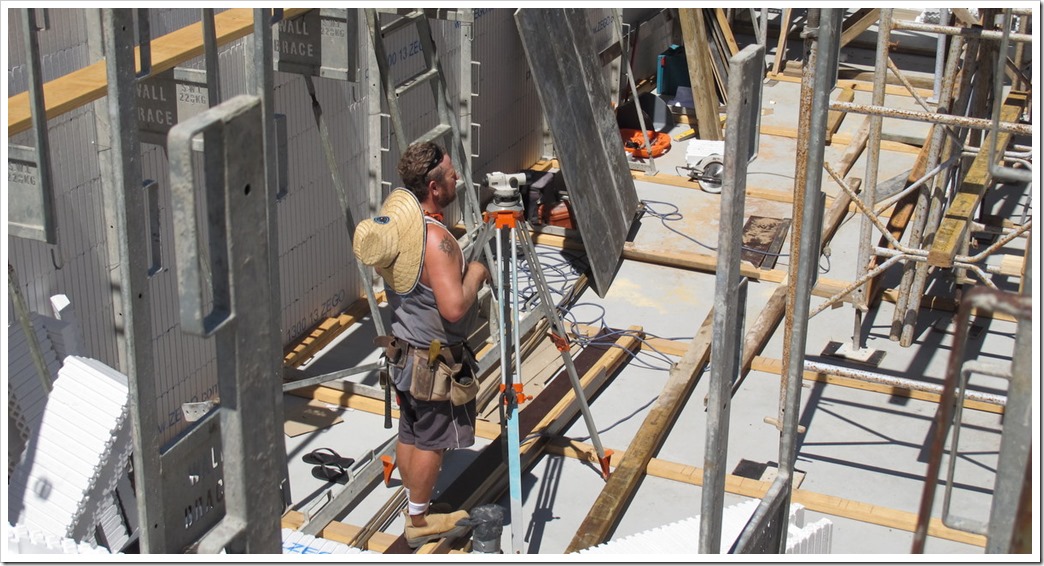

Getting heights and levels correct – I hope!

Meanwhile the walls were getting tie-wired and plumbed.

I had a few design issues and was lucky to get Harry on site for a quick inspection – not sure if he liked what he saw??! 😉

Beam Scaffolding complete!

Reinforcing steel inside the beam formwork.

Jose dropped by to help with some housework pre pour.

And before long we were ready to go…

Thursday 19th December, Chris pulled up in his Boom Pump truck and with another cracker day, we were ready to begin the last and most stressful part of this stage.

Chris all smiles… at the beginning.

Boom pump in place, and the first concrete truck arrives.

Let the pouring begin!

It was all hands on deck and not many pictures were taken in the first hour… then the first of a number of mini-disasters happened – first one of the walls blew out and we spilled about 2 wheel barrows of concrete… Peter was straight on the tools and managed to fix the problem fast.

Peter installing a retaining solution to keep everything in place.

Meanwhile, I was on clean up duties – working on preventing the concrete from setting on our brand new slab…

Then, mini disaster #2 occurred Peter and Trevor had a fiery argument and after a lot of yelling and screaming, Peter resigned… taking with him his great workmanship, his skills and all of his tools – which meant we were down to Trevor and myself and no tools – this was turning into a comedy of errors!

Then as I was cleaning up another part of the site, I heard the sound of huge amounts of concrete spilling… I ran over to see Trevor dangling from the scaffolding with his foot firmly jammed in a hole in the wall… below was….

… this sight… it was turning into a looooong day!

Trevor and I worked till 9:00pm, cleaning up and watering down all the spilled concrete – the conversation was strained and as much as there was an end in sight, I would be lying if I said I was a happy customer – the day was a shambles from beginning to end, and as much as there are always unavoidable issues on site, there seemed to be a multitude of user errors that were totally avoidable, and for every thing that went right, there was an equal and opposite thing that went wrong – many a lesson were learned by yours truly that day.

In saying that – we managed to pour 14 cubic meters of concrete into the walls and beams – understaffed and starting behind the eight ball as the first concrete truck didn’t arrive till midday… we managed to get it done – time will tell if the haste and the under-resourced crew will mean that future problems will develop…

I was back on site at 7:00 am to begin the clean up…

I started by taking 1.5 tonnes of leftover concrete lumps to the recycling centre.

Then Trevor and I started stripping the wall braces.

We worked till 2:00pm when Trevor took off for a long drive to Jindabyne… I pushed on into the evening… the site was starting to come back to some form of control and i was keen to leave it in a good state before taking off up the coast for xmas.

Front entrance and garage cleaned up….

Getting there….and so on the morning of the 21st of December 2013 I closed up the site for the final time for the year and took off up the coast!

It’s going fast! Whow!